What is a dosing pump?

Dosing pumps are used to move, inject or dose a chemical in any type of fluid, either in line or in a storage tank.

A dosing pump must always allow the adjustment of the flow in a linear way and its design must guarantee the reproducibility, the repeatability and the pressure of the displaced volume, in short it must be precise with the volume that it is dosing.

On the market there are different types of pumps for different applications with different degrees of maximum error in their dosage, as well as different materials for the pump parts, flows and maximum working back pressure.

These units are generally oscillating volumetric pumps. These suck a defined volume of liquid and introduce it into the dosing line. Different adjustments can be made to achieve a constant exact dosage.

Types of dosing pumps:

Dosing pumps can be classified by their technology:

- Diaphragm metering pumps (mechanical deflection diaphragm).

- Hydraulic diaphragm metering pumps (hydraulic diverting diaphragm).

- Plunger dosing pumps.

- Peristaltic pumps.

Diaphragm dosing pumps:

In this type of pump, the pressure of the membranes carry out a thrust that generates the dosage. Among the benefits of these systems is that they do not need sealing systems (sealing is a property that is based on the ability to prevent external particles from entering the interior of a piece), they are easy to maintain and repair. They have a good level of precision as long as you work within the design range of the equipment.

Hydraulic diaphragm dosing pumps:

These pumps are characterized by their ability to work at high pressures, pumping non-lubricating liquids or even small particles and working dry without damaging the pump. They are ideal pumps for many demanding applications, such as chemical injection into boilers and cooling towers, isocyanate dosing and industrial chemical dosing.

Plunger dosing pumps:

As soon as the plunger enters the interior of the dosing head, the suction valve closes and the dosing medium flows through the discharge valve and out of the dosing head. As soon as the piston moves in the opposite direction, the discharge valve is closed by the negative pressure of the dosing head and fresh dosing medium enters the dosing head through the suction valve. This ensures very accurate dosing.

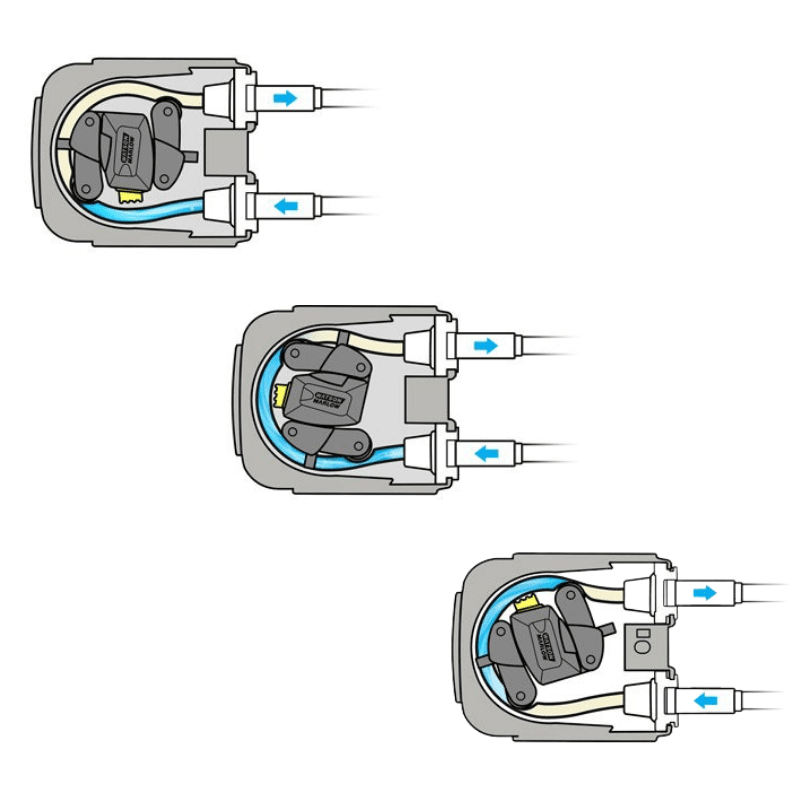

Peristaltic dosing pumps:

They are characterized by their wide chemical compatibility and their precision in dispensing chemicals in small quantities. The hose is located in the casing and is constricted by rollers mounted on a rotor. The rotary movement of the rotor moves the choke point in the desired pumping direction and the medium is mobilized. After the roller has compressed the medium by pressing the hose into the dosing head, the hose relaxes again. When returning to its position, the hose generates a vacuum that draws in the medium. The pumping volume can be increased linearly by increasing the rotor speed.

Or by the pump drive system:

- Magnetic dosing pumps.

- Motor dosing pumps.

- Pneumatic dosing pumps.

Peristaltic metering pump operating example:

How to choose a dosing pump?

In order to select a suitable dosing pump, these data must be taken into account:

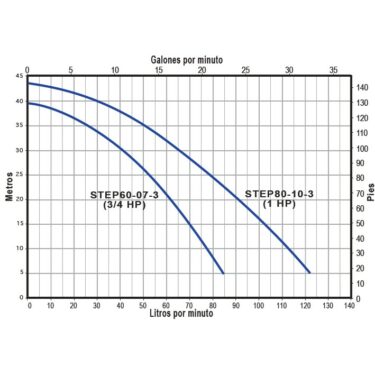

- The necessary dosage in L / h.

- Determine the back pressure (this must be higher than the pressure of the line or equipment to which you want to dose).

- Using a graph of pump performance (pressure versus flow), find an intersection between the two values.

To select a pump, the chemical compatibility of the pump materials with the substance to be dosed must be taken into account, since if it is not done correctly, the life time or the correct functioning of our equipment will be affected.

It is also important to select the appropriate type of pump according to the working conditions and the volume to be dosed, it is important to bear in mind that there is always a maximum error in dosing (this happens in all pumps and in all equipment measurement in general), so if it is critical to our process that the dosage is accurate, it will be necessary to choose a pump with a low % error to avoid deviations in it.

There is in the market the possibility of connecting the dosing pumps to control systems to be able to control our variable of interest in a more precise and automated way where a sensor sends a signal to our control system and it acts by increasing and decreasing the dosage of our pump.

Do you require advice and prices for dosing pumps?

Contact Us: 33 38340906 or leave us a message:

Le invitamos a compartir este artículo:

Escríbanos.

Algunos productos que le pueden interesar

References:

Prominent: https: //www.prominent.com.mx

Técnica de fluidos: https: //www.tecnicafluidos.es