What is the particle size or mesh number of a granular medium?

Granulometry, also known as mesh number, is the size distribution of a grain, be it sands, gravels, activated carbon, anthracite, zeolite and a wide range of other granular media. The particle size is normally expressed in the U.S. Standard Sieve test with the aid of a sieve or stack of sieves.

Screening is a method of separating a mixture of grains or particles into two or more size fractions; oversize materials are trapped above one screen, while undersize materials can pass through and be retained by other, lower screens.

Screens or sieves can be used in piles to divide grains into various size fractions and thus determine particle size distributions. Screens are generally used for particle sizes larger than approximately 50 microns (0.050 mm).

Each mesh or sieve is represented by a number that indicates the number of crossed threads per square inch, for example: mesh number 8 has 8 vertical threads and 8 horizontal threads, forming a grid for each square inch.

The particle sizes of granular media used in water treatment are expressed in two figures, for example, an activated carbon of 8 x 30 mesh or particle size means a range of particles passing through the 8 mesh and retained in the 30 mesh; this indicates that the particle size or particle size range is from 2.38 mm to 0.595 mm.

U.S. Standard Sieve Number Conversion Chart to millimeters and inches

TABLE:

Mesh Number

(U.S. STD. Sieve) |

Opening (mm)

|

Opening (in)

|

4

|

4.76 |

0.187

|

5

|

4.00

|

0.157

|

6

|

3.35 |

0.132

|

8

|

2.38 |

0.0937

|

10

|

2.00 |

0.0787

|

12

|

1.68 |

0.0661

|

14

|

1.41 |

0.0555

|

16

|

1.19 |

0.0469

|

18

|

1.00 |

0.0394

|

20

|

0.841 |

0.0331

|

25

|

0.707 |

0.0278

|

30

|

0.595 |

0.0234

|

35

|

0.500 |

0.0197

|

40

|

0.420 |

0.0165

|

45

|

0.354 |

0.0139

|

50

|

0.297 |

0.0117

|

60

|

0.250 |

0.0098

|

70

|

0.210 |

0.0083

|

80

|

0.177 |

0.0070

|

100

|

0.149 |

0.0059

|

200

|

0.074 |

0.0029

|

325

|

0.044 |

0.0017

|

400

|

0.037 |

0.0014 |

What is effective particle size?

Filter media size is commonly specified in terms of effective size and uniformity coefficient, or in terms of particle size range. Effective particle size is defined as the mesh opening through which only 10% (by weight) of a representative sample of the filter media passes.

What is the uniformity coefficient?

It is the ratio calculated by dividing the mesh opening through which 60% (by weight) of a representative sample of a filter material passes by the mesh opening through which only 10% (by weight) of the sample passes.

What is the mesh size or particle size of the filter media or granular media?

Activated carbon for water treatment: 325, 200, 8×30, 12×40 and 20×50 mesh.

Activated carbon for air and gas treatment: 4×10 and 14×30

Silica sands: 10×20 and 20×30

Anthracites: #1 14×30, #1.5 10×20, #2 4×12

Zeolite: 14×40

History and Creation of the US Standard Sieve for mesh number or particle size.

The US Standard Sieve Series, commonly known as the US Standard Sieve Series, was developed in the early 20th century by the ASTM (American Society for Testing and Materials). The need for a standardized grading system arose with the rise of industrialization, where consistency and accuracy in particle size became crucial for various industrial applications, including filtration.

Structure and principle of operation

The US Standard Sieve system classifies particles based on their size using a series of mesh sieves, each with a specific number of openings per linear inch. Each sieve has a numerical designation corresponding to these openings, allowing precise categorization of particles. For example, a number 4 sieve has 4 openings per linear inch, while a number 200 sieve has 200 openings per linear inch.

Importance in the classification of filter media

In the filtration industry, particle size is crucial in determining the efficiency and capacity of a filter media. Granular filter media, such as sand or activated carbon, must have a specific particle size to ensure effective filtration and prevent the passage of unwanted contaminants. The use of the US Standard Sieve allows for accurate grading, ensuring that the filter media meets the required quality standards.

Management and regulations

Maintenance and calibration of the sieves is essential to ensure accurate and consistent results. ASTM provides detailed guidelines on the care and calibration of sieves, including methods for checking the size of apertures and recommendations for cleaning and storage of sieves.

Industrial applications

In addition to filtration, the US Standard Sieve system is used in a wide range of industries, including pharmaceutical, food, mining and construction. In each of these industries, accuracy in particle classification is crucial to the quality of the final product and the efficiency of the production process.

The US Standard Sieve particle size is a mainstay in the classification of granular and powdered filter media. Its development by ASTM and its implementation in various industries has allowed standardization that guarantees quality and efficiency in numerous processes. The understanding and proper use of this system is essential for any professional working with granular or powdered materials, ensuring accurate and reliable results.

Related articles:

Share:

If you need more information, please contact us.

Some products that may interest you

-

Turbidex Zeolite

Read more -

Filox – R for iron and manganese removal

Add to quote -

Garnet or Garnet deep bed filter media

Add to quote -

Anthracite – filter media for multimedia filters

Add to quote -

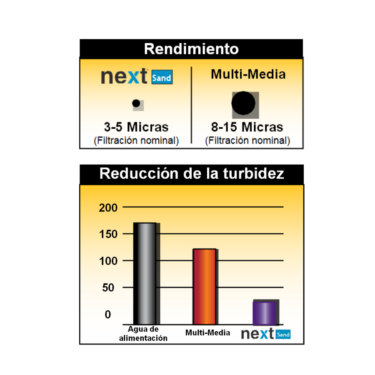

Zeolite for Water Filtration NextSand

Add to quote -

Silica Gravel Filter Media

Add to quote -

Silica Sand Filter Media

Add to quote

I enjoy your writing style truly loving this web site .

Whoah this blog is excellent i really like reading your posts. Keep up the great paintings! You already know, many persons are hunting round for this info, you can aid them greatly.

It’s great page, I was looking for something like this

very nice post, i definitely adore this website, continue it

Thank you for all your valuable hard work on this website. Betty takes pleasure in engaging in research and it’s really obvious why. I learn all relating to the lively way you render rewarding items on this blog and even improve contribution from the others on this concept so my princess is without a doubt starting to learn a lot of things. Take pleasure in the rest of the year. You have been doing a dazzling job.

I’m impressed, I have to admit. Really rarely do you encounter a weblog that’s both educative and entertaining, and without a doubt, you might have hit the nail around the head. Your notion is outstanding; the thing is a thing that insufficient consumers are speaking intelligently about. We’re happy we came across this within my hunt for some thing relating to this.

I always was concerned in this subject and still am, regards for putting up.

Thanks for this post, I am a big fan of this web site would like to proceed updated.

It’s rare knowledgeable people during this topic, however, you seem like do you know what you’re discussing! Thanks

I see something genuinely special in this site.

Keep up the good work , I read few posts on this web site and I conceive that your blog is very interesting and has sets of fantastic information.

Your article is truly informative. More than that, it’s engaging, compelling and well-written. I would desire to see even more of these types of great writing.

Aw, this has been quite a nice post. In thought I have to devote writing this way additionally – spending time and actual effort to have a really good article… but what can I say… I procrastinate alot and by no means apparently get something carried out.

This could be the ideal blog page for anybody who wants to learn about this theme. You recognize so much its nearly hard to argue with you (not that I really would want…HaHa). You definitely set a new spin on the subject matter thats been written about for years. Wonderful things, just wonderful!

very interesting subject , appreciate it for putting up.