7 steps of the typical process of purifying water for human consumption.

The supply of water for human use and consumption with adequate quality is essential to prevent the transmission of diseases and toxic effects in the body. In order to achieve this, it is necessary to establish permissible limits for its bacteriological, physical, organoleptic, chemical and radioactive characteristics. In order to ensure and preserve the quality of the water in the systems until delivery to the consumer, it must undergo a method of water purification treatments. Here are the steps in the water purification process necessary if the water is to be used for human consumption.

The water purification process consists of a physical and chemical treatment that aims to eliminate contaminants that could represent a risk. Among the contaminants we can find, microorganisms, inorganic compounds (salts, minerals, metals) and organic compounds (fats, oils, petroleum derivatives, pesticides, detergents, drugs,…).

What standards regulate the treatment of drinking water in Mexico?

In order to establish the permissible quality limits and the purification treatments of water for human use and consumption, in Mexico we are governed by the following standards:

It is important to know that the purification treatment will always depend on the parameters that need to be corrected, so it is recommended to carry out water analysis prior to determining a treatment train.

In the bottled water market, the big brands have accustomed us to the taste of low-salt water (osmotic water), but this does not mean that a purified water that is not low in salt is not suitable for consumption. In Mexico it is enough to comply with the NOM-127-SSA1-1994 to guarantee that it is safe to drink.

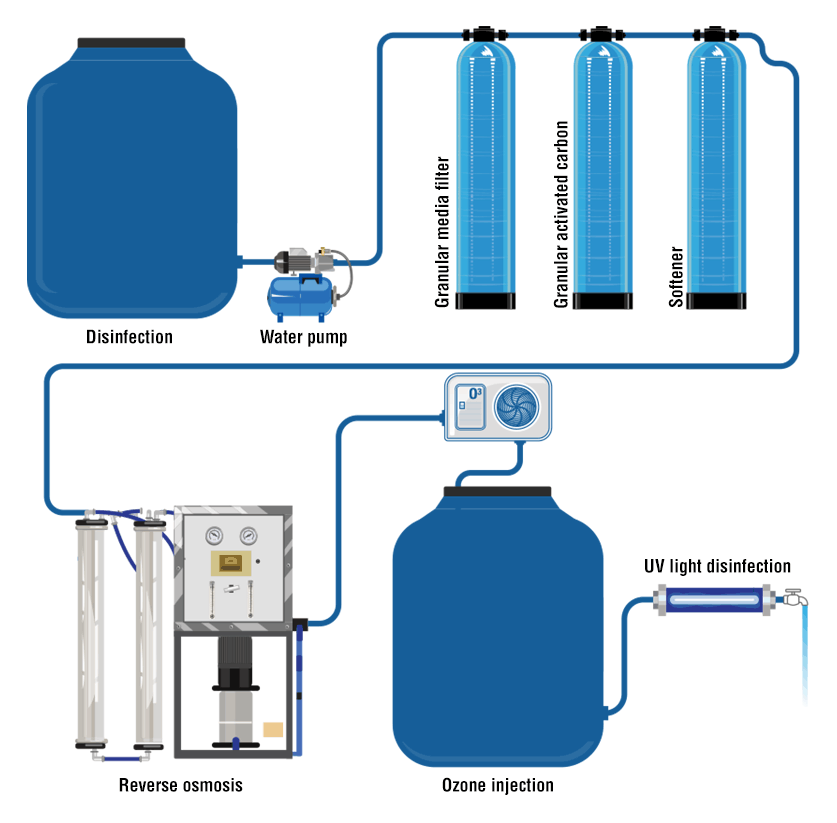

The most common stages of a water purification system are shown below:

1. Disinfection

Chlorine is the most widely used disinfectant to reduce or eliminate microorganisms, such as bacteria and viruses, that may be present in water. The addition of chlorine to drinking water has greatly reduced the risk of waterborne diseases such as diphtheria, typhoid and cholera.

Chlorination disinfects water, but does not completely purify it.

Mexican standards establish that a residual free chlorine concentration of 0.5 to 1.5 mg / l must be achieved.

2. Filtration with granular media

Filtration is the purification process that removes suspended solids from water. Filters that use granular media are also called deep-bed filters. Depending on the type of media, they can retain particles with diameters greater than 1 micron, although typically they only retain those greater than 5 to 10 microns, which may be present in the water, such as dirt, sand, silt and others. It is necessary to filter sediments in one of the first stages of the purification process in order to remove particles that could dirty or obstruct equipment used in later stages.

The most common granular media are silica sand, zeolite, anthracite, garnet or a combination of some of these in what is called a media bed.

Granular media filters require backwashing when the pressure differential between the inlet and outlet reaches 10 psi.

3. Granular activated carbon (GAC)

GAC is an excellent adsorbent of organic compounds that can be toxic or produce color, odor or taste to water.

In addition, at this stage GAC acts as a reducing agent of free chlorine which converts it into chloride ion (Cl–).

By its nature, CAG is a conducive medium for bacterial growth. Primarily, it traps organic molecules, many of which are biodegradable and provide food for these organisms. In addition, they have a rough surface that allows bacteria a good fixation that prevents water from washing them away. From this, bacterial growth is an unavoidable consequence of the operation of adsorber equipment with CAG.

There are several sanitization processes for bacterial control in activated carbon beds, which must be carried out periodically. The periodicity will depend on the effectiveness of the process, the operating conditions and the location of the equipment.

It is recommended that the GAC be changed once a year.

4. Softening

It is recommended to soften the water when it is to be osmotized and its hardness is greater than 170 mg /L . It is also recommended when it is not going to be osmotized and its value is such that it causes an unpleasant taste or that it causes incrustation in subsequent equipment. Whether a water is fouling depends on indices, such as the Langelier index, whose value is a function of hardness, pH, total dissolved solids, total alkalinity and temperature.

What is the total hardness of water?

The total hardness of water is the sum of the concentration of various divalent metal ions in the water, capable of forming scale. Normally it consists almost entirely of Ca+2 and Mg+2. For practical purposes only these two cations are considered.

For practical purposes only these two cations are considered. To soften, a negatively charged (cationic) ion exchange resin is used. These are synthetic spheres with a polymeric matrix, capable of exchanging ions in a liquid, according to their charge and intensity. Strong cationic resin is used for the softening process.

When water passes through the resin, Ca+2 and Mg+2 ions with a strong positive charge replace the lesser charged Na+ ions. In this way, the ions that cause hardness are retained in the resin spheres.

Ion exchange resins have a certain exchange capacity that is normally measured in grains per cubic foot (gr/ft3). When this limit is reached, the resin must be regenerated. The regenerant is a solution of sodium chloride (NaCl) at 10%.

It should be mentioned that hardness is not a problem that affects human health.

5. Reverse Osmosis (RO)

Osmosis of the water is only required when the aim is to reduce the concentration of salts present in it. As mentioned at the beginning of this bulletin, major brands have accustomed the public to the characteristic taste of low-salt waters.

In reverse osmosis equipment, when sufficiently high pressure is applied to the water, it is forced through a porous membrane that rejects more than 99% of the salts. This technology means that a percentage of the water fed into the system is used to reject the salts. This flow is called rejection or concentrate. The percentage of rejected water depends on the quality of the water to be treated. Depending on the case, multi-membrane equipment is designed with serial or parallel arrangements.

Reverse osmosis membranes.

There are different types of membranes on the market: high productivity, high rejection, brackish water, to mention a few. The differences in their design and manufacturing materials give them different capacities both in operation flow and in percentage of salt rejection.

Membranes can be embedded with carbonates, silica, organic matter or microorganisms. When this happens, they can be treated in situ or sent to be de-scaled by suitable chemicals.

Before entering the RO, a cartridge filter is placed in order to retain solid particles larger than 1 micron, which would not have been retained in the previous equipment or from the same. This is a final protection for the RO.

6. Ozone

At this point in a treatment train, the water is already purified and suitable for drinking. However, it is necessary to use disinfection methods to protect the water from bacterial contamination from external sources after the RO.

The ozone generation process starts with molecular oxygen (O2), which passes through a special chamber where it is exposed to an electrical charge with sufficient voltage to break the covalent bond of O2 and recombine into triatomic oxygen molecules (O3, Ozone). This type of ozone generation is known as “corona discharge”.

The O3 is injected in the form of bubbles into a residence tank or by suction with the help of a ventury, directly into the product water pipe to make it reach the treated water storage tank.

Ozonization leaves a residue that is useful when water is packaged in recyclable barrels that may have been left with some bacterial contamination after the washing process.

7. UV light sterilizer

As a last stage of sterilization and prior to bottling, as a second protective barrier, an ultraviolet (UV) light lamp is used in which the water passes through a chamber that integrates a source of UV light of the appropriate wavelength to prevent bacterial or viral reproduction and proliferation if present.

Depending on the brand, UV lamp bulbs have different average half-lives, although in general it is 9000 hours.

There are other systems used in the water purification process, these are the most common and those that are needed in the purification of water in Mexico.

If you need advice, design and recommendation of a complete water treatment plant, contact us at: (33) 3834 0906 or leave us your message:

Comparte:

Necesitas más información, escríbenos.

Algunos productos que te pueden interesar

-

RoClean L211 cleaning of membranes with organic matter fouling

Add to quote

-

RoQuest 3000 Organic Liquid Coagulant from Avista

Add to quote

-

Titan Antifouling for Reverse Osmosis Membranes

Select options

-

RoClean P112 Membrane Cleaner for Silica SiO2

Add to quote

-

RoClean P303 Calcium Carbonate & Metal Scale Cleaner

Add to quote

-

RoClean P111 Biofouling RO Membrane Cleaner

Add to quote

-

RoClean L403 Calcium Carbonate and Metal Scale Cleaner by Avista

Add to quote

-

RoQuest 4000 Liquid Coagulant for Organic Matter Avista

Add to quote

Comparte:

Necesitas más información, escríbenos.

Algunos productos que te pueden interesar

-

RoClean L211 cleaning of membranes with organic matter fouling

Add to quote -

RoQuest 3000 Organic Liquid Coagulant from Avista

Add to quote -

Titan Antifouling for Reverse Osmosis Membranes

Select options -

RoClean P112 Membrane Cleaner for Silica SiO2

Add to quote -

RoClean P303 Calcium Carbonate & Metal Scale Cleaner

Add to quote -

RoClean P111 Biofouling RO Membrane Cleaner

Add to quote -

RoClean L403 Calcium Carbonate and Metal Scale Cleaner by Avista

Add to quote -

RoQuest 4000 Liquid Coagulant for Organic Matter Avista

Add to quote